Types of Manufacturing processes play a catalyst role to producing any item. To developed any physical products whether it is the form of plastic product, sheet metal product or other material product it must be produced with the help of any manufacturing processes. Basically, whatever we seen at nearest environment during our day to day activity, whether it is helpful for improving our lifestyle, whether it is useful to reducing our efforts to doing a particular task, each and every item is produced with the help of manufacturing processes. Each types of manufacturing processes are the core part of operation management.

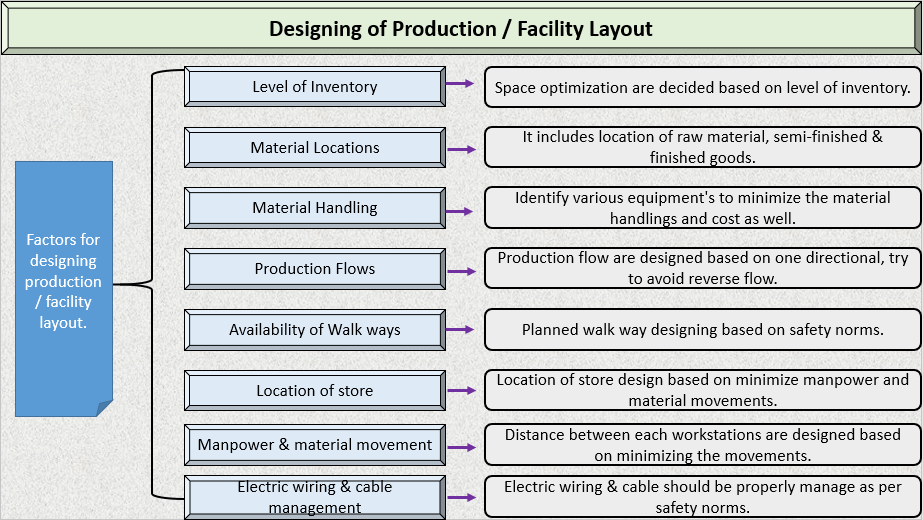

Effective production layout provide the healthy environment for manufacturing processes. It is also very helpful for capacity planning & process optimization.

What is Manufacturing process?

Each types of manufacturing processes are defined as to providing the platform and systems to conversing raw material to finished products with the help of various resources such as manpower, machines, money and environment. To producing various products with effective output, manufacturing process optimization is very essential. Now technology is drastically change day to day basis and sustaining with the competitive environment adoption of technology is very important and it is very important to understand about the technology life cycle.

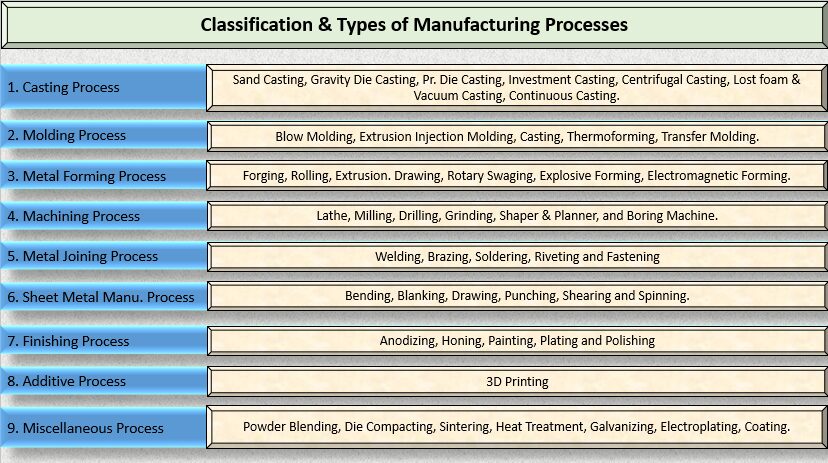

Classification and types of manufacturing processes.

Types of manufacturing process can be classified according to the methodology follow during producing product with maintaining required dimension and material property as per the customer requirement. Manufacturing process can be dividing into 9 main types as per listed below.

1. Casting: –

Casting process defined with developing product to melting metal and pouring into appropriate cavity and wait for solidification, after solidification remove the runners and burrs from the final product. Mainly casting process described in three steps molten metal preparation with the help of foundry, metal pouring into the desirable cavity, removing other parts from cavity and segregate the final product. During molten metal preparations, initially metal scrap parts and other metal component added into melting foundry as per the specification required in the final product and cavity preparation according to size of the final product.

Majority those products are developed by casting process, it required machining in second stage because casting process not provide the accurate finishing. So, mainly in casting process product dimensions are decided with the addition of machining tolerance for final use of product. Majority of automotive component are developed with the help of casting process. Various types of casting process are listed below.

- Sand casting

- Gravity die casting

- Pressure die casting

- Investment casting

- Centrifugal casting

- Lost foam casting

- Vacuum casting

- Continuous casting

2. Molding Process: –

Molding process is the types of manufacturing processes to applicable for plastic products. Molding process is defined as initially small size of plastic grains is heated more than its plastic deformation and its pressurized enter into die, then plastic metal takes the shape of the die cavity and after solidifies plastic product is ready. In molding process solidification time is not much more. Review the below attached different types of molding process.

- Blow molding

- Extrusion injection molding

- Casting

- Thermoforming

- Transfer molding

3. Metal Forming: –

Metal forming process modify the product dimensions with the help of external pressure or force applied with the help of various equipment and tools into base metal and modified the product dimension as well as achieving required material properties. In metal forming process converting the base metal into plastic deformation and change its shape as per required dimensions with maintaining properties. Metal forming process performed in two ways such as hot forming and cold forming. According to achieving material properties and current dimension of products hot forming and cold forming process is selected. Metal forming is the very important types of manufacturing processes and there are several types of metal forming processes as per mention below.

- Forging

- Rolling

- Extrusion

- Drawing

- Rotary swaging

- Explosive forming

- Electromagnetic forming

4. Machining Process: –

Machining process is also called as metal removing process. In the machining process either the workpiece has been rotating or the cutting tool has been rotating and remove the workpiece extra material with the help of various cutting tool. Machining process is help to achieve the critical dimensions in micros. To achieving critical dimensions of various products after the forging, casting and joining process machining is carried out. There are various machines available in the market to perform machining process. Review below attached machines that are used in machining process.

- Lathe machine

- Milling machine

- Drilling machine

- Grinding machine

- Shaper machine

- Boring machine

5. Metal Joining Process: –

Metal joining process is create the joint between two parts or components either join same metal or different metal, either applying pressure or not, either addition of external consumable or not and either creates permanent or temporary joint. According to the requirement of the final joint, joining process has been decided. Metal joining process broadly classified as per below.

- Permanent Joint

- Welding

- Brazing

- Soldering

- Riveting

- Temporary Joint

- Fastening (screw & nut)

6. Sheet Metal Manufacturing Process: –

For producing various types of sheet metal products, sheet metal manufacturing process is used. It includes removing extra metal and modify the shape of applying external pressure. Now in manufacturing world there are various types of products available that developed by the sheet metal manufacturing processes. Review below attached sheet metal manufacturing processes as per below mention.

- Bending

- Blanking

- Drawing

- Punching

- Shearing

- Spinning

7. Finishing Process: –

Finishing process is improving the finishing of product surface. There are several ways to use finishing process such as achieving micro finishing on products surface and to avoid corrosion, wear and chemical resistance to product surface. Review the listed finishing process as per below.

- Anodizing

- Honing

- Painting

- Plating

- Polishing

8. Additive Manufacturing Process: –

Additive manufacturing is defined to developing various products with the help of layer production. Layer production means produce product with layer by layer according to product dimensions. Mainly 3D printing technology is used in additive manufacturing process. To developing the any new product, initially its prototype making is very important to check its visibility and performance. To developing prototype now a days additive manufacturing processes really helpful.

9. Miscellaneous Manufacturing Process: –

Miscellaneous process means such manufacturing processes are difficult to categorize in a sequential way and it is applicable in special purpose to producing various products. Review the below attached list of miscellaneous processes.

- Die compacting

- Sintering

- Heat treatment

- Galvanizing

- Electroplating

- Coating

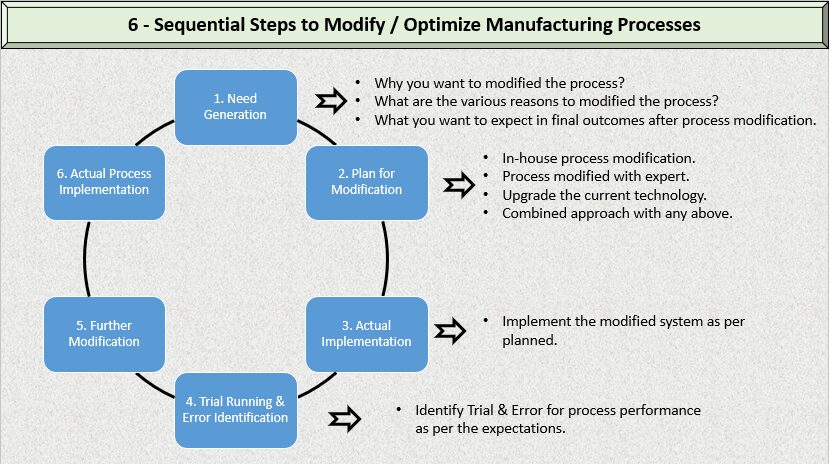

Sequential steps to modified the manufacturing processes.

As per the above types of manufacturing processes help to produce product but organization want to improve process efficiency or final output process modification or optimization play a very important role. It helps to create strong business impact financially. The sequential steps can be divided into 6 parts as per below mention and its cycle is continuously repeated whether expected outcomes is not achieved.

1. Need Generation: –

Initially three questions are very important to identify the requirement to modified the process as per mention below.

- Why you want to modified the process?

- What are the various reasons to modified the process?

- What you want to expect in final outcomes after process modification?

2. Plan for Modification: –

After the process modification need identification, market research is very important to identify how we modified the process. Team work play a vital role because various brainstorming session with team work get the various ideas to work on process modification. In process modification many important steps play important role as per below.

- In-house process modification.

- Process modified with expert.

- Upgrade the current technology.

- Combined approach with any above.

3. Actual Implementation: –

After the process modified and actual implementation stage currently you are at the research and development stage. You initially developed one model, if it fulfils your requirement then you plan for horizontal deployment across the processes. In-house process modification is a very challenging task because you developed something not in existing.

4. Trial running and error identification: –

After the model preparation few days or month you plan to trial the manufacturing process and check whether targeted output is achieved with the process modification. If not achieve the targeted output with process modification then, identify various errors or the various reason for modified process not fulfilling the requirements and record the documents.

5. Further Modification: –

As per the report of trial and error identification again modified the process as per user requirement.

6. Actual Process Implementation: –

If trial and error report of manufacturing processes is accepted then plan to horizontal deployment or implement in another areas. If the report is not accepting then process modification cycle is repeated.

Conclusion: –

In this article we learn types of manufacturing processes and 6 effective sequential steps to optimize the manufacturing processes. Now a days as pet the technology upgradation point of view each and every day process is modified as per the product demand and customer requirements. Each organization mainly focused on to improving production output with the help of manufacturing processes. For improving output process flexibility and reliability is very important. Each manufacturing process has the expertise in individual areas and sometimes it also useful multiple combinations. So, regularly process modification is the key to success for any business environment.

Frequently asked questions about the manufacturing processes.

What are the sequential steps to modified the manufacturing process?

1. Need generation

2. Plan for modification

3. Actual implementation

4. Trial running and error identification

5. Further modification

6. Actual process implementation

What are the types of manufacturing process?

Manufacturing process broadly categorized into 9 different types as per below.

1. Casting

2. Molding

3. Metal forming

4. Machining process

5. Metal joining process

6. Sheet metal manufacturing process

7. Finishing process

8. Additive manufacturing process

9. Miscellaneous process.

What is manufacturing process?

Each types of manufacturing processes are defined as to providing the platform and systems to conversing raw material to finished products with the help of various resources such as manpower, machines, money and environment. To producing various products with effective output, manufacturing process optimization is very essential. Now technology is drastically change day to day basis and sustaining with the competitive environment adoption of technology is very important and it is very important to understand about the technology life cycle.