Material handling equipment is used to transfer material from one place to another place. Any form of material can be transfer with the help of material handling equipment such as raw material, semi-finished material and finished material. For financial stability manufacturing organizations initially used simple & low-cost material handling equipment. Each equipment’s having certain advantages and limitation based on its design criteria as well as usage of automations. Material handling equipment help to managing internal inventory and right selection of handling equipment’s help to minimize the time and cost as well.

Now a day’s technologies are drastically changing day after day and manufacturing sectors also growing day after day so, for managing operations in the manufacturing organizations material handling equipment play a vital role and it helps to optimize overall operational processes. According to study report out of the total factory cost 25% cost consumed by material handling in manufacturing equipment’s and its varies industry to industry.

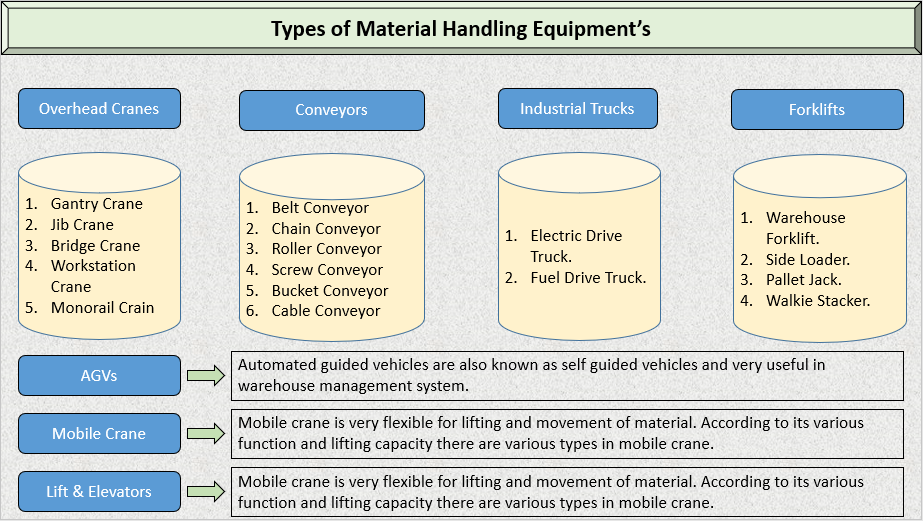

Types of Material handling equipment’s.

There are several types of material handling equipment’s as per its usage criteria, we will discuss each equipment in detail as per below.

Overhead Cranes: –

Overhead cranes one of the largely used material handling equipment to move material in a fixed path. Overhead crane is designed based on various metal support structures, hoists, wire rope and lifting hook. Safety criteria is completely match at the overhead crane design stage. For overhead crane movement in a fixed path RCC or metal structure has been created before crane installation.

Each overhead crane is designed based on it lifting weight capacity such as 20 MT, 25 MT, 150 MT and many more as per the customer requirements.

There are several types of overhead cranes are available in the market based on its function and design as per mention below.

1. Gantry Crane: –

Gantry crane is majority used in outdoor activity of material handling. The main component of gantry crane design is to supportive metal leg, bridge and hoist. Gantry crane horizontally move from one place to another place and for smoother movement of crane I – section track will be fixed on floor. There are several types of gantry crane available as per design and lifting capacity as per below.

- One bridge one hoist gantry crane.

- One bridge multiple hoist gantry crane.

- Two bridge one hoist gantry crane.

- Two bridge multiple hoist gantry crane.

Examples of Gantry crane usage

- Scrap Yard: – Managing scrap within yard or scrap loading & unloading.

- Ship Yard: – To managing container within yard or ship loading.

- Steel mills: – To lifting steel billets, plates, rods, angles etc.

- Manufacturing facilities: – for material loading & unloading via trucks.

2. Jib Crane: –

Jib crane is a type of overhead crane and material handling equipment to move material of 360 degree with the support of center support column. The basic structure of jib crane looks like the cantilever support with column or wall. There are three main component of jib crane such as support column, bridge and hoist. Basically, jib crane is design to lift light weight objects and mostly used in within workstations. In majority case single hoist jib crane is most popular to handling the material. Jib crane rotational degree is basically set with manual guided movements, sometimes stopper is attached to restrict job crane movement as per the requirement. Type of jib cranes are mention below.

- Wall mounted jib crane.

- Pillar mounted jib crane.

3. Bridge Crane: –

Bridge crane is generally mounted on RCC or metal structure and horizontal movement done by the wheels and transverse movement done by the hoist and sometimes vice versa. The main component of bridge crane is to hoist and bridge. Mostly, bridge crane is used in-door application to movement of various material in selected path. There are several types of bridge crane as per the bridge and hoist usage as per below.

- Single bridge & single hoist bridge crane.

- Single bridge & multiple hoist bridge crane.

- Double bridge & single hoist bridge crane.

- Double bridge & double hoist bridge crane.

4. Workstation Crane: –

workstation crane is design based on fulfilling workstation requirements. Mainly movement of workstation crane is restricted within workstation area. Design of workstation crane is similar to bridge crane and crane support structures developed within workstation area.

5. Monorail Crane: –

Monorail crane design is not similar to bridge crane. In monorail crane, rail is designed in the form of curve within fixed path and crane follow the curve movement as per designed. In monorail crane, upside and downside material movement is possible. Monorail crane doesn’t able to move material in horizontal or transverse direction, it only follow the designed path.

Conveyors: –

Conveyors are a popular type of material handling equipment’s and majority used in continuous production system. The type of conveyor is used according to the product range such as belt conveyor, chain conveyor, bucket conveyor, roller conveyor, screw conveyor & customized conveyor. Majority in assembly line products are move with the help of various conveyor in fixed or variable interval. Conveyors are installed to move various products in fixed path.

Industrial Trucks: –

Industrial truck is one of the popular material handling equipment’s. Industrial trucks are generally used to transfer material for long distance such as one factory to another. There are various types of industrial trucks available in the market according to its weight capacity. For distributing various material industrial trucks are mainly divided into two types such as electric drive industrial truck and fuel drive industrial truck.

Forklifts: –

Forklift is a type of material handling equipment’s, used within organization for material movement. To usage of forklift material handling flexibility will be achieved. For safely material handling forklift is popular in various organizations. Forklift is a manually operated material handling equipment’s. Forklift types are mainly divided according to its function such as warehouse forklift, side loader, pallet jack and walkie stacker.

Mobile Crane: –

Mobile crane is type of hydra for handling material from one place to another place. Mobile crane is majority used to transfer heavy products or items. Mobile cranes are easily accessible with all the roads and manufacturing facilities. With the help of hydraulic mechanism, wire rope & lifting hook hydra is manually operated.

Automated Guided Vehicles (AGVs): –

Automated guided vehicles is the automatic material handling equipment’s to operate without human intervention. AGVs is generally used in warehouse material handling. There are multiple AGVs working for material movement in one warehouse for predefined multiple path.

Lifts & Elevators: –

Lift and elevators are used to move material at height. In Construction site and multiple floor manufacturing unit lift and elevators are used to transfer material from down to top or top to down.

There are other various material handling equipment’s available in the market to transfer material or items from one place to another place such as tractor with trolley, manual material handling with trolley, manual handling, various automatic robots for pick up and drop various items and many more. Now a day’s very important logic is to everyone focused to minimize material handling time with maintaining safety at workplace.

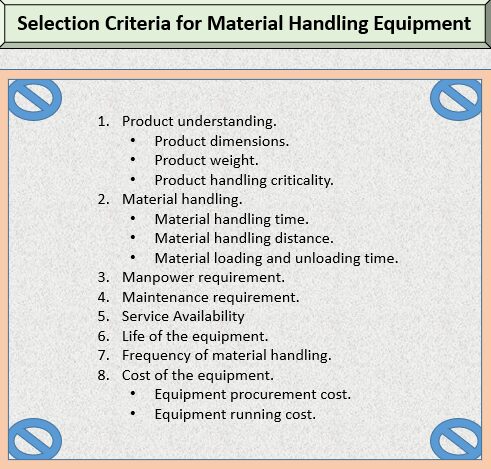

What are the selection criteria for material handling equipment?

Basically, any organization or individual procure the material handling equipment to fulfil their purpose and expectation whether it is financially, economically or functionally. Safely material handling is also one of the important factors with minimizing environmental impact on carbon emission. There are several criteria to selecting material handling equipment based on various parameters.

1. Product Understanding: –

Before selecting material handling equipment, product variations understanding is very important. Few important parameters where you want to analyze the product as per below mention.

- Product dimensions.

- Product Weight.

- Product handling criticality.

2. Material Handling: –

Material handling means movement of material from one place to another. To conduct the accurate analysis of material handling, below mention parameters play a important role.

- Material handling time.

- Material handling distance.

- Material loading and unloading time.

3. Manpower Requirement: –

If you analyze the manpower requirement with comparing to material handling equipment it varies equipment to equipment. Few equipment’s are able to manage with one manpower and few required three manpower according to equipment construction. Manpower requirement parameters directly impacting on the operational fixed cost.

4. Maintenance Requirement: –

Before selecting the equipment, routine or condition-based maintenance requirement verify with the material handling equipment manufacturer. Maintenance cost also financial impact to the organization. So, select the equipment with the easy maintainability.

5. Service Availability: –

After sales service is provided by the material handling equipment manufacturer. According to equipment’s brand its service varies, take the feedback from various users that already used equipment and select the material handling equipment according to easy service availability.

6. Life of the Equipment: –

Life of material handling equipment is dependent on the various parameters such as operating condition, frequency of use, usage according as per the capacity and many more.

7, Frequency of Material Handling: –

Frequency of material handling define the service life of the material handling equipment. If your material handling frequency is too high or too low so, select the equipment accordingly with the calculation of loading, unloading and handling time.

8. Cost of the Equipment: –

Cost of the equipment play a major role for selecting material handling equipment. Equipment cost is mainly categorized into two parts as per mention below. For selecting equipment summation of both cost help to make the economical decision.

- Equipment procurement cost.

- Equipment running cost.

In concluding part material handling equipment can be broadly classified as three categories such as manually operated, semi-automatically operated and fully automatically operated. Manually operated means to fulfil the requirement for material movement, special tool design (for ex. Manual trolley, manual pallet) that operate with the one or two manpower and move the material. Semi-automatically operated means above listed all the majority equipment are the semi-automatically operated rather than AGVs. In semi-automatic category equipment operated with the help of human and fuel as well as electrical drive. and full automated equipment point of view AGVs and automatic warehouse management system is operated with the help of program and software and they are mostly following the electrical or battery drive system.

Frequently asked questions about material handling equipment.

What are the cost should consider before procuring material handling equipment?

For selecting equipment summation of both cost help to make the economical decision.

1. Equipment procurement cost and

2. Equipment running cost.

What are the 8 effective selection criteria for material handling?

1. Product understanding

2. Material handling

3. Manpower requirement

4. Maintenance requirement

5. Service availability

6. Life of the equipment

7. Frequency of material handling

8. Cost of the equipment.

What are the types of material handling equipment’s?

There are several types of material handling equipment’s as per its usage criteria.

1. Overhead cranes

2. Conveyors

3. Industrial trucks

4. Forklifts

5. Mobile crane

6. Automated guided vehicles

7. Lift and elevators.